Cryogenic Level Monitoring Systems

Reliable and accurate capacitive measurement solutions for liquefied gases

Typical Applications:

- Cryogenic fuel tanks in aerospace and automotive sectors: Level monitoring and threshold detection for LH₂, LOx, LN₂, LCH₄ …. in both stationary and mobile tanks.

- Ground testing & storage: Used in cryo test stands and ground support equipment (GSE) for rocket propulsion and liquid gas distribution.

- Industrial and medical cryo applications: Tank monitoring in gas supply systems, cryogenic medicine, and liquefied gas production lines.

- Hydrogen refueling stations: Real-time level monitoring of LH₂ in distribution units and transportable vessels.

- Redundant safety chain integration: level switch system used as a threshold alarm for safety-critical cryogenic fill cycles. For instance 90% and adjustable on demand.

FOGALE’s systems are field-proven in multiple liquefied gas applications. The measurement chain is scalable for different tank volumes and installation requirements.

What are our Liquid Gas Level Measurement Systems made of?

FOGALE’s capacitive sensing solutions for liquified gas measurement combine highresolution level sensing with robust architecture suitable for harsh cryogenic conditions.

System Chain for Continuous Measurement (illustrated hexagons):

- Capacitive sensor Probe (Embedded electrode in perforated tube, immersed and installed through feedthrough)

- Low-noise triaxial cable (standard lengths or customized)

- Capacitive conditioning module, Analog Output

System Chain for Level Detection Only (ie 90% fill detection):

- Capacitive sensor Probe

- Capacitive conditioning module

- On/Off level signal output

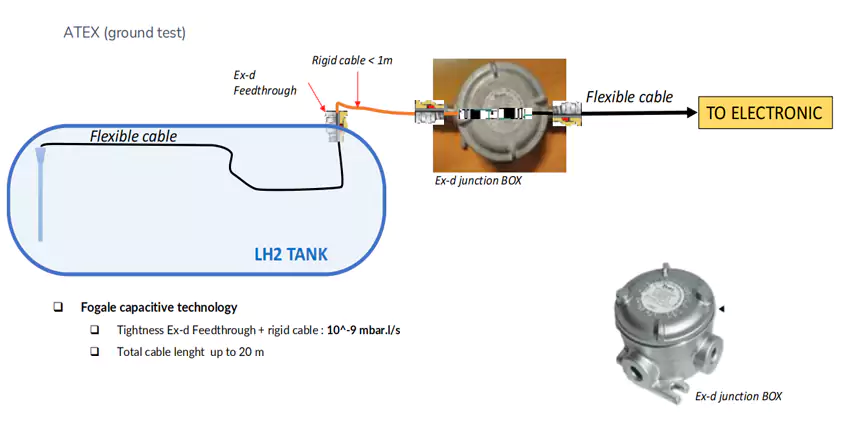

ATEX-compatible feedthrough and junction box (optional)

Main Advantages

- Versatile sensor architectures: Supports continuous level measurement or discrete threshold detection depending on application.

- High accuracy, high stability: Submillimeter-level resolution over full range, insensitive to vibration or pressure variation.

- Extreme cryo compatibility: Proven performance in LH₂, LOx, LCH₄, LN₂ … tanks, up to 10 bar and above,down to –253 °C (20K).

- Maintenance-friendly design: Sensor probe can be extracted for servicing without draining the tank, improving productivity. The sensor is flexible and can also be installed in existing tube.

- Signal integrity with triaxial cable: No parasitic capacitance; stable output over time and temperature.

- Dual function option: Combined use of analog monitoring and digital switching improves system safety and flexibility.

- ATEX-ready: Compatible with Ex-d feedthroughs and enclosures for hazardous areas.

- Turnkey solution: Full chain: probe, conditioner, cabling, and integration accessories available.

- Architecture designed to remain virtually unaffected by liquid sloshing or movement within the reservoir, ensuring rapid stabilization for seamless performance.

Continuous Measurement Chain

Capacitive Probe

- Installation: Immersed in tank via perforated grounded tube (typically 10–11mm ID)

- Electrode: Flexible, Ø1–2 mm in a tube with typical diameter 10mm to 15mm

- Range: Adaptable to tank dimensions

- Pressure: typically 3.5 to 10 bar and more on request

- Operating Temp: -253°C to +85°C (20K to 358K)

- Weight: ~440g (probe + tube) for a one meter

- Typical Accuracy: < ±0.5 % over full range

- Measured Capacitance: ΔCmax ~6.6 pF

Probe Connection

ATEX Ex2 (if requested) : Using adapted cable gland, mineral cable section and Atex EX2 interconnexion box

Outer tank cable + Inner tank cable : Up to 20m With FOGALE conditioner (see below) and soft triaxial cable equipped with dedicated connector

Capacitive Conditioning Module

- MC900 or CS200 or MCI930 (miniaturized)

- Ultra-low drift electronics

- No signal loss or leakage

- Configurable output : typically Analog: 0–10V output proportional to fill level

- Option: ATEX Ex-d connector boxes

- EMC-optimized

Level Detection / Electronics / Accessorie

Level Detection Probe – ie 90% Fill

- On/Off capacitive probe with discrete logic

- TTL output triggered when tank reaches threshold level

- Fast reaction time

- Mounted in corresponding tank area

Cable & Connector Options:

- Flexible cryo cables (20m max total length)

- ATEX rigid feedthrough < 1m

- Ex-d junction box as an option